Our Sun Pod

The Sun Pond symbolises our commitment to environmental stewardship. We are dedicated to ensuring transparency in our sourcing of raw materials and our tannery operations, enabling us to be accountable for our ongoing efforts to reduce our environmental footprint. We actively engage with independent stakeholders to uphold our commitment to fostering a sustainable future through responsible leather production.

Climate Action

We firmly believe that leather stands as one of the most sustainable materials available, primarily due to its inherent recycling nature. Our process involves transforming a by-product into a valuable commodity through the application of science, skill, technique, and genuine care. At Mossop, we annually convert thousands of tons of waste, originally destined for landfill, into high-quality leather utilised in various products such as footwear, belts, and furniture.

Our raw hides are responsibly sourced from the by-products of pasture-raised cattle within the food industry. By ensuring responsible sourcing and manufacturing practices, we guarantee that the end consumer receives a durable, anti-fast fashion product, thereby contributing to less waste in landfills. Embracing the principles of reducing, reusing, and recycling our waste aligns with our commitment to minimising our climate impact.

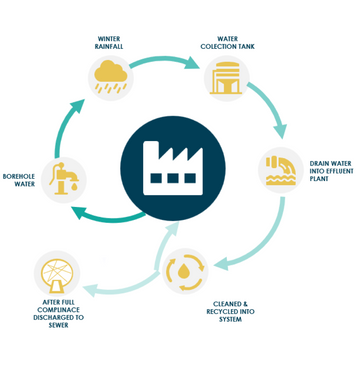

Our Clean Water & Sanitation

Ensuring that we process our water correctly and responsibly is crucial for safeguarding our environment and the ecosystems it supports. It's worth noting that our effluent undergoes treatment to meet the rigorous standards set by our local municipality. Additionally, we carry out weekly tests on our discharged effluent at an accredited laboratory to ensure complete compliance with regulations.

Life on Land

In South Africa, our diverse landscape includes natural Savannah terrains reminiscent of the Rangelands and Australian Alps montane grasslands, historically supporting varied herbivore populations. Our suppliers meticulously manage extensive grazing areas, employing strategic monitoring for rotational grazing of pasture-raised, grain-fed cattle, and implementing waterstream rehabilitation to combat soil erosion. After rearing, the cattle are processed for the food industry, generating hides as a byproduct. These hides, crucial to the tannery industry, are processed by local Wetblue tanneries, limiting our carbon footprint.

Over 90% of our rawhides are locally sourced, ensuring real-time traceability and environmental responsibility. Adherence to animal husbandry and safety regulations, including electronic identification tagging, guarantees full traceability from farm to final product, supporting our responsible manufacturing process and guiding customers towards lower environmental impact.